Orthodontist Dr. Michael Mahaffey regularly creates custom aligners for his patient’s teeth in his 3D printer. So when the call came up from the Georgia Dental Association for orthodontists with 3D printers to consider making facemasks for the medical community during the COVID-19 crisis, Dr. Mahaffey does what he always does, he looked for the best possible way to do it. And how to share it with as many people as possible.

“We wanted to do something, try to help because it seems like the potential for running out of PPE is real,” said Dr. Mahaffey.

He contacted his colleague, Dr. Vinny Perciaccante of South OMS. Dr. Perciaccante had contacts at the hospital, and he also 3D prints.

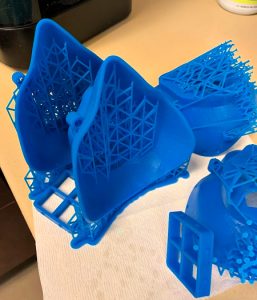

They downloaded a mask design called the Billings Clinic Mask. Dr. Mahaffey and Dr. Perciaccante found some design aspects they wanted to change. So they enlisted a friend of Dr. Mahaffey’s son, a 4th year Georgia Tech biomedical engineering student, Sharnali Ghoshdastidar to help them redesign that mask for better fit, functionality, and usage of resources.

After she had left the Georgia Tech campus due to the COVID-19 shutdown, Ghoshdastidar remoted into the campus computers to use CAD tools in the SOLIDWORKS software to design edits to the mask from her home in Charlotte, North Carolina.

“Dr. Mahaffey sent me the changes he wanted to make to this mask. This would be a replacement for an N95 mask if they have no other options. These masks would be 3D printable, and they would have a compartment where you could change out the filter. This mask was already designed by someone else and ready to be 3D printed, but Dr. Mahaffey wanted some edits to make it easier for doctors to use, to make it more comfortable for doctors,” she said.

Ghoshdastidar added indentations around the edges so that material would adhere to make the fit custom. “We wanted to make something that would be more comfortable for doctors to wear for 12 hours at a time,” she said.

Over the course of about one week, Ghoshdastidar did four sets of modifications and iterations. Those included removing enough of the 3D printable material to make the masks lighter, but not so light that it would break. She explained that these edits made it print faster and reduced the cost. She also edited the placement of the loops for straps to make it more comfortable for doctors.

On this project, Ghoshdastidar described working with Dr. Mahaffey, “It was really nice. He’s very responsive. He’s really clear in his instructions. It was just a really good project to work on. It was a great way to keep up my skills. It was really nice to know that I was doing my little part to try and help all the doctors that are currently fighting this crisis.”

Dr. Mahaffey was very satisfied with the results of their work together, too. He said the mask is much improved. “It’s lighter, uses less resin to print faster, and uses a smaller piece of filtering material for each use,” said Dr. Mahaffey.

Including beta tests with some practitioners, the process took three weeks.

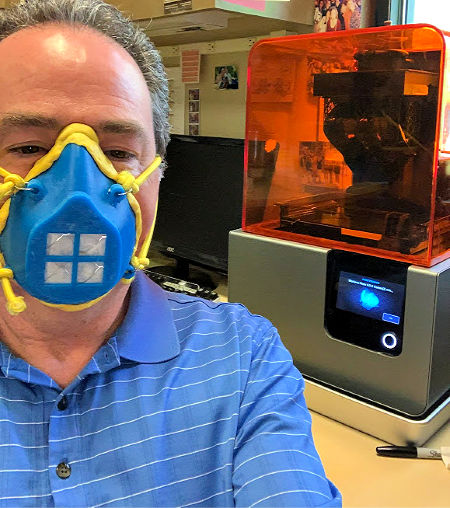

The new Billings -Peachtree City Mask has a plastic mold that fits over the nose and mouth with a hole in the front in which a replaceable filter can rest. It requires a filter with Minimum Efficiency Reporting Value (MERV) of 13 or higher. Those are readily available HEPA filters or air conditioning filters. Dr. Mahaffey says it’s a simple process both to find and cut the air conditioner filter, and although he cautions that these aren’t FDA approved, he says they are said to function as the equivalent of an N95.

He’s got an orthodontist’s trick to make it fit perfectly. “To make it comfortable and a good seal around the outside of the plastic that fits on your face, we have a dental molding material called PVS, polyvinyl siloxane. PVS is what we typically would use to make a mold of your teeth with to get a crown or Invisalign. This mask uses a little bit of PVS against the face to make a custom fit.” Weather-stripping material is also an option to create the edge seal for those without access to PVS material.

Dr. Mahaffey sent masks to his niece and her husband who are medical doctors at Walter Reed and might be deployed to New York City to the front lines of COVID-19.

He also gave one to home hospice nurse Cynthia S., showing her how to mold it to her face. She said, “Like everyone else in healthcare, we have a shortage of personal protective equipment. So it’s a Godsend, and I consider it a lifesaver to me. Not only do I not want to get sick, but my biggest fear is to pick up the COVID-19 virus and carry it to one of my patients. And, of course, if you’re on hospice you are in one of the most vulnerable groups of people.”

“It sure is helping me because I had one N-95 that I had been using for a couple of weeks. Now I have this mask that is reusable, and I feel like it’s safe to wipe that whole thing down with our germicidal wipes that kill everything. And it has the replaceable filter in it, so it’s like a brand new mask every single day. Or it can even be a brand new mask in between patients,” said Cynthia.

Dr. Mahaffey and Mahaffey Orthodontics have customizable, reusable masks available to healthcare workers. “We have been 3d printing masks for our colleagues in the dental, nursing, and medical fields as well as first responders,” said Dr. Mahaffey.

Any healthcare professional who wants one of these masks may email Dr. Mahaffey for details at [email protected]. There is limited stock available.

The Billings – Peachtree City Mask design is available as a free download for any other dental or orthodontic offices, or people with a 3D printer who want to print masks at peachtreecitybraces.com/mask.

Leave a Comment

You must be logged in to post a comment.